Between June and October 2021, we fought to get on our land. It was a tougher fight than we could have ever anticipated. It was clear we weren’t getting up that driveway the way it was. Not with the truck and definitely not with the trailer. We stepped back to consider our options.

During those few days of considering our options the phone rang and we learned the barn wood order was ready for pickup. I won’t lie, there was a tiny bit of panic because we had nowhere to put all that wood! We had to get on the property one way or another. Thankfully the mill agreed to hold the wood until we had the driveway figured out.

Andy — our first dirt work contractor was not gong to finish the job. That was beyond clear.

It was a shock to the system to realize that paying good money for a service didn’t guarantee you’d get the help you needed — but there it was. We paid for a service we didn’t get and there was little we could do about it. While one might expect that in a big city it wasn’t expected in a small town.

Before the plandemic…

…dirt work contractors were drumming up work wherever they could get it and struggling for it. During the fraud perpetrated on the whole world …and after? Things were different. There was a windfall and everyone seemed to be getting while the getting was good — and we were stuck right in the middle of it.

Dirt workers were in such demand with the influx of people fleeing blue states for the safety of the Ozarks that whatever they wanted to charge — and whatever they chose to deliver — was going to have to do. I had no idea just how much things could swing in so short a time.

After 18 months of delays and thousands of our homesteading budget dollars spent treading water — we were not OK spending more money on dirt work before knowing exactly what we wanted to do and more importantly — needed to do.

I can’t stress enough how important it is to know your property very well before you start altering the landscape permanently. You want to know exactly where the best spot is for everything you want on your land. Don’t guess or you could end up regretting it. We knew that — but we were also in a difficult spot.

There are hundreds of things to consider when placing buildings on a piece of property. How does the water run? Where is water going to pool? What’s going on with the trees? How does the sun travel over your property? Which way do storms normally blow in? What is it like in winter versus summer? These are only a few of dozens of things you need to know when determining how to use your land.

When we got to Arkansas in June, we knew we didn’t have the advantage of spending significant time on the property in advance as we had planned. Lock downs shattered that plan.

We knew we would have to wing it for our first driveway and clearing just to get on the land to get started. It would have to be a best guess. We counted on our first dirt contractor to advise and I won’t say he mislead us — but I can say it certainly could have been better!

One thing that James and I knew for sure was — it made no sense to spend another $10,000 on dirt work before knowing our land better.

No. We had to figure this out on our own. The time had come for a completely different approach.

Once we came to these conclusions I went to work looking for the tools we would need to work on the driveway ourselves… the hard way …by hand.

Over the next couple of weeks — armed with a very serious wheelbarrow, a few digging tools and a lot of sweat and determination, we managed to get the driveway to a point where the truck could make it up to the clearing for the first time. That was mid-July 2021.

We knew it wouldn’t be a permanent solution but it was a small victory and a significant step forward.

Time to go fetch our wood!

We placed the order over-the-phone so we had no idea “the wood mill” was just a little section on a homestead out in the country. The first time we saw the mill was the day of the pickup after a 45 mile drive through the Arkansas back country — to a respectable little homestead in the woods.

The lumber mill was a small father/son operation that took up a corner of their property. They had a nice commercial band saw mounted on a platform under a tin roof with a massive pile of sawdust off to the side. There were no under-cover storage sheds. No massive stacks of wood or logs. They literally went out and cut trees for each order.

Unfortunately, our freshly cut wood had been sitting in the rain for weeks. Uncovered. Every board was covered with mold and mildew. That was a big disappointment but there was no turning back now. With the help of the younger son and his forklift the three of us loaded the wood on our truck. Once it was all aboard we paid the bill, shook the young man’s hand and thanked them for holding our wood until we could pick it up.

mold was everywhere on nearly every board

4,000 pounds of green pine covered with mold was now on our truck. The nose of our old Ford F350 was pointing to the sky under all that weight and made the trip back home just fine. Of course we added an upgraded suspension for the Ford to our laundry list of future fixes! Have a look at how close the body of the truck was sitting to the tires!

4,000 lbs of wood

Check out the suspension problem!

Barn wood finally coming home.

By the time darkness was beginning to descend over the mountain, we had the wood off-loaded. It was temporarily stacked on several pallets we brought with us from St. Louis.

temporarily stacked on the pallets

I was adamant about bringing the pallets with us so we could build our first compost bin. I didn’t want to assume we could find good pallets in Arkansas with all that was going on at the time. Strong pallets aren’t always easy to find and I sourced four excellent pallets before we left St. Louis. At least we’d be able to build one good compost bin as soon as we got on the property.

When we needed those pallets for the barn wood James stopped moaning about why in the world I wanted to pack pallets for our trip. LOL The pallets were perfect to stack the wood temporarily and keep the wood out of the dirt/mud.

we were two very tired — but happy — people

At the mill we had a third person and a forklift. At the property we had four hands — two of mine and two of James. It took awhile.

Once everything we finally unloaded, we kissed it all goodnight and took off for the RV park for a desperately needed shower, some dinner and a few hours of research to find out how to kill mold and mildew on green wood.

I did discover that Clorox is not an option. While it might be the first thing that comes to mind for killing mold and bleaching wood back to its original color, it drives mold deeper into the fibers. Once that mold goes deeper in the wood it will go dormant until the slightest bit of moisture comes along and gives it a whole new life at some point in the future. The correct solution is BORAX, VINEGAR and WATER! A good strong solution does the job.

NEXT MORNING

In any case, the next morning we hit the local hardware store — grabbed some scrub brushes (one with a long handle), some Borax and Vinegar and headed to the property to start scrubbing all that mold away!

this was the next day… ready to start scrubbing!

quite a job in 100 degree weather…

One step forward — two steps back.

I have noticed that doing anything on raw land is like a dance. You take one step forward and two steps back. Our barn wood is a perfect example.

We needed to clean the wood, right? But before that can be done you need a place a to put it after it’s cleaned off the ground. That meant we needed a drying booth. No point in scrubbing every single board with nowhere to put it.

Our finished drying booth

BUT…

Before we could build a drying booth we had to gather materials.

materials are all around us… just have to go get’em!

AND…

Before we could gather those materials — we had to pull out chainsaws that neither of us had used before and figure them out.

The moment of truth arrived.

We had to get building materials for the drying booth and that meant cutting a few tress. It was time for both of us to get chainsaw experience in the wild!

Our chainsaw jitters faded quickly into a healthy respect for the tool and we managed to collect all the logs we needed over the course of a couple of days. We kept our tree selections on the smaller side — not more than 3 or 4 inch thickness. It was all we needed.

getting comfortable with the chainsaws

Chainsaw experience in the wild!

this wasn’t my first tree — the first one was a 2” thick sapling LOL

just making sure it’s not going to fall on my head!

after felling that huge tree!

ask us how we know that getting DIRT into the bark will dull your drawknife!

AND YES — there’s more…

If you cut down trees to build something you have to take the bark off. You can build with logs that still have bark on them — just don’t expect it to last long. Critters will gladly eat your building in fairly short order. And that means… you need a place to debark the logs which means you need a heavy sawhorse.

We made a sawhorse with a few hand tools. Our first one 🙂

If you don’t have a good sawhorse? — you’ve got to build one before you cut down the trees! Plastic sawhorses found in every Home Depot won’t do. The sawhorses have to be heavy enough to hold a log.

AND even more…

Cut logs cannot get in the dirt. NO DIRT in the bark if it can possibly be helped which means you cannot drag them.

If dirt gets in the bark your drawknife will get dull within a few strokes and slow the whole process to a crawl. That means you need a place to put the cut trees you cut — up off the ground — until you’re ready to debark them.

See what I mean?

There are at least two steps back to take one step forward.

The drying booth dimensions had to be 20 feet long, 8.5 feet wide and 5 feet high to accommodate all the different sizes of wood in our pile. (You saw our finished “drying booth” above 🙂

And just in case you’re wondering we didn’t build anything fancy. We used bushcraft techniques to build the drying booth since we only had hand tools, parachute cord, a hammer and some nails.

We did collect fallen branches — which were dry — making it possible to use nails for some of the construction. But the freshly cut wood? — that would have to be secured using bushcraft knots.

dropped limbs we collected were dry — beginning to build the booth around the stacked wood…

The materials for the booth were sitting all around us. All we had to do was go get it which meant we had to learned how to use the brand new chainsaws we had in the back seat of the truck. Chainsaws we had never used before.

Of the four chainsaws we brought with us to Arkansas, two were electric and two were gas-powered. We had used electric saws so that was no big deal. But the two gas-powered saws were new to us. Both were made by Stihl and thankfully Stihl offered an online class about how to use them safely.

The online class wasn’t our only instruction. I promise!

While we were staying at the Bear’s house, Larry, a neighbor who owned a landscape business and and did some of the work around the Bear’s house in preparation for the sale, turned out to be an excellent source of instruction. He was more than willing to show us how to use a chainsaw while staying alive and healthy at the same time.

The first thing we had to build…

The first thing we built was the sawhorse. A good sturdy but simple design which we knocked out in a day.

splitting a log with an axe and a homemade mallet to build the sawhorse

getting the first side done

almost finished

first sawhorse goes to work!

Tree barking was a different matter. With a sawhorse you can stand upright while using the drawknife. It takes two people without proper tools — which we didn’t have.

We strapped the log to the sawhorse, leaving most of the log hanging in the air. One of us held the log in place while turning it as needed and the other stripped the bark. We took turns doing this since it wears you out pretty quickly if you’re not used to it — and neither of us were used to it by a longshot.

standing up to use a drawknife or saw

one of us held the log while the other stripped the bark

I can tell you there’s something incredibly satisfying about barking a tree. It’s easy to get into a zone — a kind of zen space where the sound of the knife slicing between the meat of the tree and the bark is just so relaxing. There are other times however — especially with hardwoods — where it’s nothing but hard work!

Once the drying booth was built we started scrubbing and cleaning the boards.

note: you do get bark everywhere… including in your underwear! hahaha

The Borax solution worked beautifully.

We spent many days under a sweltering August sun cleaning every inch of every board. As each board was scrubbed with solution, it was stacked up in order from the largest at the bottom to the smallest at the top. We cut stickers to put between every layer so air could circulate around all the pieces.

wood before scrubbing

stacked from longest to shortest!

taking a break in 100 degree temps!

all that’s left is battening down the top on our drying booth!

barn wood tucked in for a drying nap!

The Pile

Our excitement about building the barn was growing with every board we cleaned — but — once again we knew it would take two steps back before we could actually build anything. We had that massive pile of bull-dozed tress, under brush and rocks to deal with first.

Try to imagine a pile of full-grown trees with root balls attached and rocks in a pile that’s 50 feet long, 30 feet deep and 40 feet high. How do you move that?

THE PILE1

the pile in the back doesn’t look as big in the picture as it actually was… and well, still is.

A new plan is hatched!

I had been looking at old farm tractors for a while. To be honest, I fell head-over-heels in love with them before I ever saw one face-to-face.

I joined an old tractor group on Facebook and several vintage tractor groups online. I even have an entire playlist of videos on YouTube about the history of those original tractors, how to fix them and how to refurbish them.

There are plenty of old 50-to-60 year-old tractors still in use today on farms all over the world — and there’s no reason not to consider an old farm tractor to do work on a small acreage.

To give you some idea how plentiful they are — the Fordson was made by Ford, in collaboration with England during the first world war, starting in 1907 and sold 650,000 units worldwide. The next Ford tractor called the 9N, started in America in 1928 and sold 530,000 worldwide. Those were only two of many companies. The Massey-Ferguson which happens to be one of my favorites was also a massive hit around the world.

What makes these old tractors useful is their simplicity. They were designed to be reliable workhorses. They’re easy to fix and quite literally can run forever. Parts are plentiful. Today there are many modern manufacturers that make parts to keep these old beasts running.

A tractor was on my “tool list” for the property long before we started seriously looking for land.

Back in 2015, 2016 — when I knew I wanted one — an old tractor could be scooped up for $500 to $1,200 depending on the condition. Many were refurbished or at the very least, upgraded from 6-volt systems to 12-volt systems.

Today?

These tractors are fetching twice those prices and more due to both the homestead craze and the blue-state exodus. Still — the cost of an old farm tractor with some implements is less than the cost of a new tractor by a long-shot and apparently a lot less than one phase of dirt work!

While an old tractor won’t completely replace what modern machines can do, it can go a long way to building up a property.

Spending two thousand — or even five thousand to get an old farm tractor is just plain smart. Since we were willing to put in the time, effort and sweat equity an old tractor made more sense by the day..

By August of 2021, intent on maximizing every dollar of our dwindling budget, we had to face the fact that we were going to have to do more on our own than we originally thought when it came to the dirt work.

With a tractor — even an old girl from the 30’s, 40’s or 50’s — we could grade the clearing, level a spot for the trailer, move large rocks and downsize that massive pile sitting on the spot for the barn. We could even move logs and spread rock.

Getting on a property and building a place we could love and enjoy was never about speed or size. We never planned to build the Taj Mahal or a massive plantation. It was about doing something — together — learning, building skills, enjoying the process and sharing it with others. It was never about how much it cost or how big it had to be.

I would even venture to say there’s always been an underlying current for both of us to prove to ourselves that it is possible to have more of what you truly want for less cash outlay, by putting in the work. Why have someone else’s vision of a house when you could make your own? There’s an old saying in the alternative building world that houses made of earth aren’t built… they grow out of the ground. A rather romantic idea I suppose.

Once the barn wood was tucked in for some drying time — we decided sitting in the County RV Park no longer made sense. We went to Arkansas on a mission to get the land cleared and set things up so we could bring our other vehicles and tools down after. We expected the fact-finding mission would take a week or two. By mid-August we had been in Arkansas for nearly two months and could still only get the truck on the property.

Back to St. Louis!

We broke down our little camp at the County RV park and headed for St. Louis within a day after the barn wood was cleaned and stacked.

Back in St. Louis the first order of business would be getting our 1969 Airstream out of mothballs where it had been since 2014 when we went to work with Conway Truckload — and get it sold.

the Airstream needed a bath!

Instead of taking it to the property — as originally planned — to do needed repairs and turn it into a wonderful little guest house, we decided to sell it.

It was a tough decision to sell the Airstream after 21 years of ownership BUT — our plate was now full to overflowing.

A 1969 Airstream could fetch a good price as a true American icon. Ours had the original airplane skin that can be polished to a mirrored finish — and it was time to move on. The Airstream sold quickly to exactly the right person. The proceeds from the sale gave our homestead budget a much needed facelift and I still cried like a baby when it rolled away with its new owner.

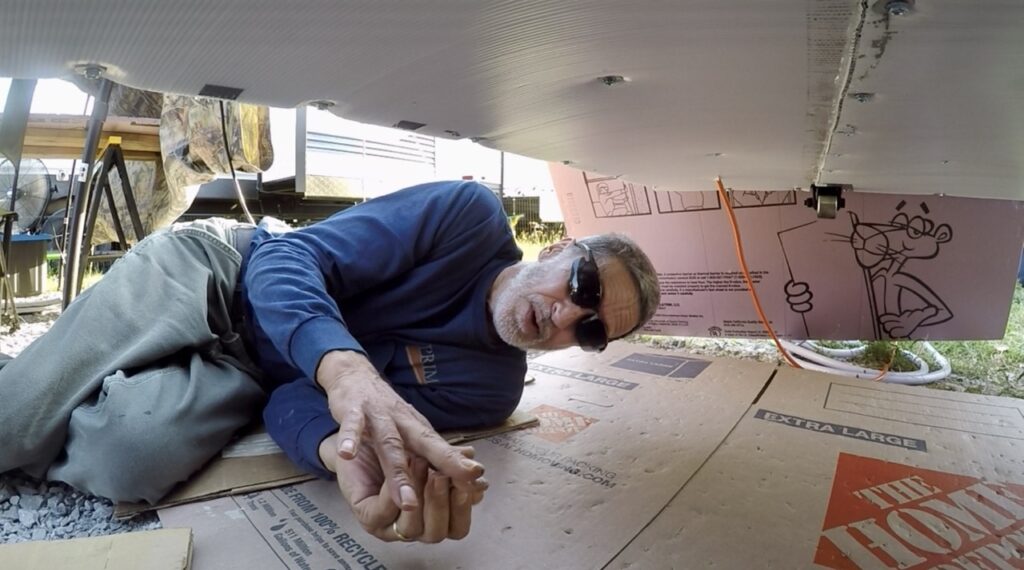

Next up was the belly pan!

After realizing my mistake of not putting in air conditioning, I didn’t want to compound that in the winter by not insulating and sealing the belly pan in the Thunderbilt! (our utility trailer turned living space). I didn’t do it during the build and winter was indeed coming. We were able to get the belly pan done while staying in a cute little RV park in a cornfield in Illinois. As long as no one was inconvenienced, we could work on the trailer… thankfully! We had the belly pan all insulated and buttoned up for winter — and critters — within a week.

Between visits to see the Bear’s at their Assisted Living Community — which were 20 minutes max per visit and only twice a week — we began our tractor hunt!

The Illinois/Missouri area turned out to be good hunting ground for old tractors.

After a few days spent cruising the ads on Craigslist, in local papers and on Facebook, we had a list, of tractor owners to call. Out of all those calls we were able to make several appointments and started our tractor hunting journey in earnest.

For all the high hopes we had when we started on this hunt — upon arriving at the farm, horse barn, ranch or someone’s house — we found ourselves disappointed time and time again.

After a couple of weeks of looking at tractors that either didn’t run or did run but not very well or had a plethora of problems covered up by pretty paint jobs — which made me begin to be suspicious of any tractor with a new paint job — we finally met a seller who did have a good little tractor.

Jake, was a collector of projects. He had a barn full of tractors from garden tractors to full-sized farm tractors that he was always fixing up. He didn’t worry about how they looked. He only paid attention to how they ran.

Jakes tractor for sale was a Ford 8N. Jakes tractor was so ugly it was cute! Have you seen something like that? Aside from being ugly it was in decent shape and looked like a good buy. James and I liked the way the tractor ran but we wanted to do a little bit more research on a few things about this tractor before committing. We asked Jake for one night to think about it. He agreed to give us one day.

the tractor that got away!

That night on YouTube, I found the info I needed and James and I decided this one was a Go! We called Jake the next day to tell him we were ready to come pick it up — only to hear him say a guy showed up with cash-in-hand and it was sold. That was that.

A few weeks later we found the next “good buy”. Not wanting to repeat the same mistake — we jumped too fast. Let me explain….

I found an ad on Facebook for a Ford 8N that looked and sounded great. It was a good distance away from us — but after talking to Dave, the owner — it sounded like it would be worth the drive. That’s when Dave gave us directions to the horse farm where he worked.

By that time we had been to several horse farms during our tractor hunting journey. We didn’t think much of going to another one. When we got to the farm it was clear this wasn’t just another horse farm. This was a massive farm with thousands acres of rolling pasture and hay fields. We learned later that it is the largest horse and feed ranch in the state of Illinois.

The day after our call, we followed Dave’s direction and found ourselves on a meandering driveway that passed under living arches made by the limbs of 400 year-old oak trees that brought us up to an iconic big red barn with the little Ford 8N tractor parked in front.

Dave said he could show us the tractor at the end of his workday so it was late afternoon by the time we arrived. Evening shadows were getting long and the air was crisp when we climbed out of the truck to greet one another.

We shook hands with Dave who gave us a warm welcome. We asked a few questions about the farm and learned it was owned by his Aunt and Uncle. He had worked there his whole life and appeared to be a man of about 30. He bought and sold and fixed all the equipment on the ranch — even had several personal projects going on the side due to having an amazing shop to work out of — and the little Ford 8N had been his baby for the last 17 years.

“Why are you selling it?” I asked.

“Well, I haven’t used it all that much over this last year. It’s mostly used for brush hogging but now I have that thing over there”, he turned and pointed to an enormous blue tractor where a driver seat that sat a good 10 feet off the ground, “that’s the big girl now.”

He turned again and pointed to the 8N sitting a few feet away, “This little Ford has been sitting and now with two big tractors to keep up with I thought it was time to get her a new home”.

While looking for a tractor, I realized we needed a way to get it from St. Louis to Arkansas. That meant that we needed a trailer. While hunting for a tractor I started looking for a trailer too. A 16 footer would do the trick but every used trailer I found through online and local ads — that was in decent shape — turned out to be more than what we would spend on the tractor!

It occurred to me while we stood there talking to Dave, that a farm of this size might have an old 16 foot trailer sitting around somewhere. I asked the question and what do you know! — Dave said he thought they might have one sitting in a back field somewhere.

Before we even talked any further about the tractor or went to look it over, Dave decided we should go check on the trailer first.

Dave disappeared for a few minutes and returned with a little golf cart type of buggy and told us to hop on. He took off down a little dirt road that took us to a small field with a variety of pieces of equipment, including trailers. He pointed to a trailer and said, “That’s a 16 footer”.

We got out to have a look. The grass needed cutting but there was enough above the tall grass to see that it was in decent shape. It wasn’t perfect. There were a few pieces of bent steel here and there and a little rust but the deck boards were in excellent condition and the tires were good.

“Price?” James asked after we looked it over front to back.

“I don’t know” he replied “but I think we can work something out. I’ll call my Aunt to see if she wants to sell it and what she’ll take for it.”

We all hopped back on the cart buggy and went back to the barn.

By this time it was getting a bit dark with just enough light to have a good look at the tractor. There were no leaking seals on the axles. Always a good sign. The crankcase looked clean and the tractor had the original paint which was in great shape. No fresh paint anywhere.

I hopped on the tractor, turned the key and pushed the starter button. It started, and ran for less than 5 minutes. It puttered, choked a bit and died before I could drive it two feet.

That’s when Dave said the carburetor probably needed cleaning. He added that it had been having that issue just before it was parked but he didn’t think it was a big deal. “Probably needs a good cleaning” he said as he headed for the barn to get some tools. Dave returned and quickly removed the carb.

I spent most of my time learning about the Ford 8N and knew about the carburetor issues. There are carburetor repair kits you can pick up for a few bucks so it didn’t seem like a big deal to us either. And if we couldn’t fix it — which is usually possible — we could find a replacement part, right?

We couldn’t get the tractor to start and run long enough for a test drive but letting this deal go for a problem that was likely an easy fix didn’t seem like a good idea either. AND…

While we were all standing there talking about the carb problem, Dave’s aunt called to confirm she would sell the trailer and the package deal on the tractor and trailer was pretty sweet!

Instead of walking away, we shook on the deal, gave him the cash and agreed to take the carb with us — to get it cleaned. We would return in a day or two to test the carburetor and in the meantime Dave could get the trailer cleaned up and brought to the front for loading. AND — we’d be on our way.

We left Dave and the horse farm that night with a sense of relief. We had found our tractor and a good trailer to boot — all for a great price. All we had to do was get the carb cleaned up and installed, get the tractor loaded on our new trailer and off we could go to Arkansas and greener pastures… literally.

James put the carburetor in a coffee can filled with gasoline as soon as we got back from meeting Dave. The following day the problem was crystal clear when he laid out all the parts on some newspaper and a repair kit wouldn’t help. In the lengthening shadows of the last evening we couldn’t see it — the cast housing of the carburetor was cracked. Without the right tools and a proper shop to work in, there was no fixing it.

Undaunted, we decided to order a replacement carburetor. We called and Dave was fine if it took a few days for us to get it since it had to be shipped.

Two days later, we had the new Ford 8N carb in hand and returned to the farm where Dave popped it in. Excited to finally hear the tractor running and drive it — the result was even worse.

After spending a couple of hours trying to get the carburetor to work everyone was frustrated. The tractor was not going to run.

Dave suggested loading the tractor on the trailer and taking it to Arkansas to do the fix there. After all, we had already paid for the tractor and trailer and a deal was a deal.

The problem was getting the tractor off the trailer. There was no way to get to the carburetor if it was still on the trailer and we didn’t have a skid steer or a forklift to unload it on the other end!

After exhausting all possibilities none of us could figure a way to make this work. What if a new carburetor or an attempt to rebuild of the old one — which could take weeks to accomplish — didn’t work in the end? We’d have nothing more than 2,400 pounds of useless steel.

At the end of the whole affair Dave returned most of our money — all except the price of the trailer. We needed a trailer even if we didn’t yet have a tractor to put on it.

We shook Dave’s hand and thanked him for all his effort and left with only a 16 foot trailer.

For the next couples of weeks we drove all over Illinois and Missouri and even made one trip to Tennessee and came up tractor-less.

It wasn’t like there were no tractors in Arkansas, right? Perhaps we’d find one there. Staying in St. Louis, at the little trailer park in the cornfield was coming to an end.

A few days before we planned to head to Arkansas — tractorless — I found an ad on Facebook for a Ford 9N with 7 implements. The price was ridiculous.

I called immediately.

James and I spoke to Nick over the phone. He was a police officer with a 10 acre property in southern Missouri — some 60 miles south of St. Louis. Of all the people we spoke to through our tractor hunt journey he was the most down-to-earth and straight-forward.

“What I’m really selling”, he said, “is the implements. There’s just no reason to keep the tractor without the implements and I don’t need it anymore because we’re moving. So the tractor is kind of free.”

I knew he was speaking the truth because I had been looking at implements too. He had a scraper, two brush hogs, a box blade, a boom pole, a dump bucket and a few other items for far less than these would cost if purchased separately and that was before adding the tractor!

these are the previous tractor parents! Nick & Amy

Nick told us how he built his driveway, an add-on room on his house and several other major projects with this little tractor. He knew it well. If he was “throwing it in” then what we were getting into?

We had to see it for ourselves.

the first time was saw “TANK”!

After several phone calls, we made an appointment to see the tractor.

If the tractor was a complete loss it would still be an incredibly sweet deal to be able to get the implements — all at once — for the price Nick was asking. We had to go look.

When we got to Nick’s house and met him and the family we fell in love instantly. As it turned out both Nick and his wife Amy were police officers. That was a surprise. They had a beautiful multi-acre property, in the country with a wonderful old Victorian (from what I could tell it was an old Sears kit house from back in the 1920’s) that they had been working on for years. We met Amy’s Mom who had recently moved in with them — who needed more help these days — and fell in love with her too.

Yes, we drove the tractor and it drove great. It had a couple of obvious issues but that old girl was running and running well enough to load up on a trailer!

The implements were the real “find”. All 7 implements in one go? No hunting for each separately? And easily cost twice Nick’s asking price for the implements AND a tractor! — even if it needed copious amounts of TLC.

We met Nick and his whole family, drove the tractor and looked at every implement closely. They were all in very decent shape. Worthy of many more years of use. The tractor was working but had its idiosyncrasies according to Nick. For example, sometimes you had to pull a little white piece out and put it back in to get the tractor to start. That turned out to be part of the 12-volt system. It did have that upgrade but it wasn’t done very well. You had to wiggle this and wiggle that in just the right to get it to work — but it would work!

After our first visit to Nick’s house to see the tractor we left without making a decision.

We went home and just for good measure priced out every implement Nick was offering to see if it was truly worth it. There was no question. We’d likely never find all those implements in one place for that price.

But the tractor?

If we got to Arkansas and it died completely we could still sell it for parts. But it did run! And there was still life in the old lady.

No matter what old farm tractor you buy there are going to be repairs unless it’s been rebuilt from the ground up by an excellent mechanic — who you know very well.

It’s that simple.

I did find one tractor for sale that had been rebuilt from the ground up with exacting detail and finished out with a perfect era and year specific paint job. It was close to the price of a brand new modern tractor. Beautiful but meant to be a showpiece in a museum — not a workhorse. There is a difference.

After a few days of researching rebuild kits and parts for the possible problems with the tractor and pricing out the implements and losing a little sleep over what to do — we finally spoke to Nick on the phone.

loading the implements on our 4×8 trailer

It’s funny how people can become attached to machines. Nick had to sell his tractor because he was selling his house and property. He didn’t need it where they were moving and once we met he didn’t want anyone else but us to buy it! He had other offers but wouldn’t let anyone come see it until we made a decision. The funny thing is — we did the same thing with the Airstream. There was one buyer we really wanted to have it and held it back until he (thankfully) made the decision to take it home.

After speaking to Nick on the phone, we decided we had to see the tractor one more time We drove to his house a second time, looked everything over and ended up shaking hands on the deal and of course… giving him the money 🙂

Now, we had a tractor to load on our newly acquired 16 foot trailer — AND — seven implements weighing over 1,500 pounds on an 8 foot trailer! AND — we had to get all of that — plus our utility trailer — to Arkansas.

0 Comments