Let’s start with WHAT and then talk about HOW

In this post I’ll go over what a jake brake is and HOW to use it. Grab your hat and let’s head for the hills… after all, the jake brake is your best friend when going down Vale, Donner’s Pass, Snowqualmie and any massive mountain or little hill across the country… unless, you don’t know how to use it.

In doing a little research of my own, looking for information online about how to use a jake brake to slow a truck on a downhill run — just to see what’s out there that would explain this to a newly minted driver — I found a lot that explains what a jake brake does, a good bit about how it works and how to turn it on, which is flipping a switch, turning a knob or pulling a lever (depending on make and model)

I didn’t find what I was hoping for… practical information about how to use it.

Now, you may know about a video or article I didn’t find. If so, feel free to post a link in the comments below. I’m not saying it doesn’t exist but what I found simply didn’t provide what I was hoping for.

There are a few videos that show how to use a jake brake — but — it’s really just a view of the road from the driver’s seat while listening to straight pipes throttling down the hill. There’s some explanation about switching between low, medium and high on the jakes to keep the speed down… but overall, not a lot of detail.

Don’t get me wrong

I adore the sound of a full throated jake brake rumbling down a mountain. Wonderful!! But, I digress.

What I’d like to accomplish with this article — hopefully — is to fill the gap and give you some useful ideas for how to get up close and personal with one of the best tools you have to keep your truck and yourself healthy.

I’ll briefly explain what a jake brake is and how it works and then get to the meatiness of this article, which is how to learn to use it in real life.

Let’s Start With The 4 Stages

All internal combustion engines work in four stages to burn fuel and create what we call “horse power” or energy to move the vehicle.

- INTAKE

- COMPRESSION

- COMBUSTION

- EXHAUST

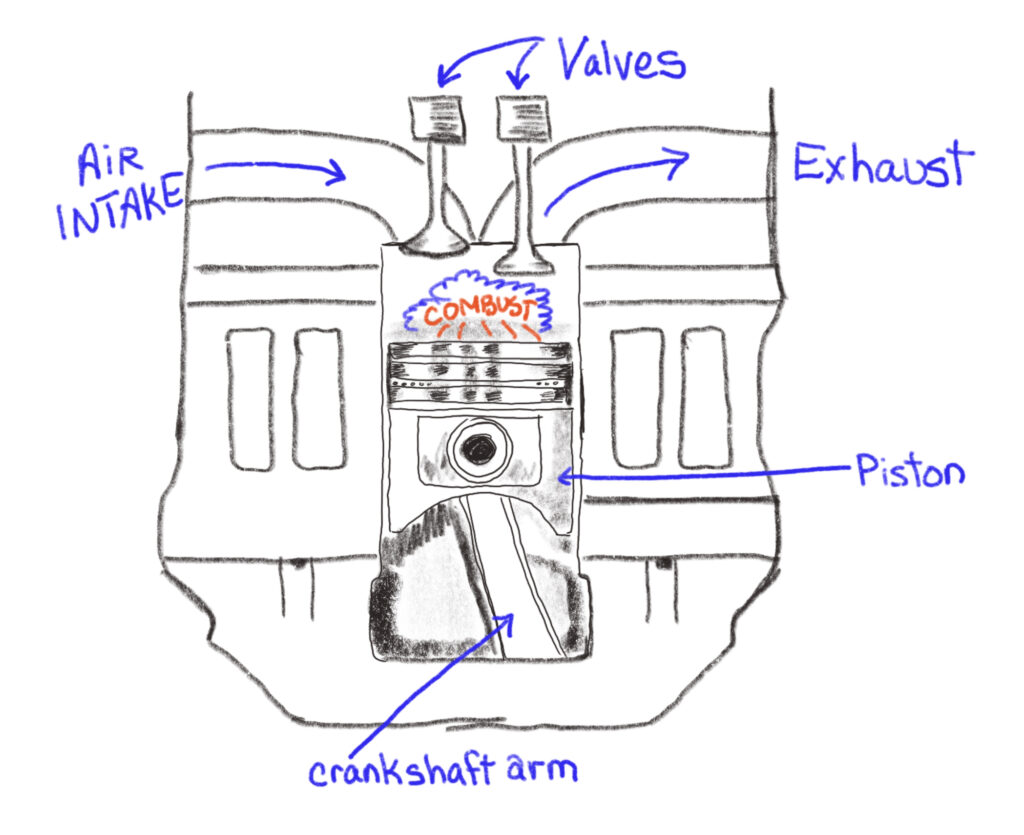

Now let’s look at each of these stages and what they do. I drew a little picture to help you visualize the process… pardon the simplicity of the sketch it’s just to give you an idea of how this works… to make it a little more clear.

INTAKE

The piston is pulled DOWN by the rotation of the crankshaft and the intake valve opens (the one on the left in the pic). This creates a vaccum in the cylinder which is filled with air. (NOTE: A turbo-charged engine works slightly differently in that the turbo-charger forces air into the cylinder.)

COMPRESSION

Next is the compression stage is where the piston is pushed UP by the crankshaft, the intake valve is closed which causes the air inside the cylinder to compress.

COMBUSTION

Next, combustion is what happens when the air/fuel mixture is explodes which pushes the piston back DOWN. NOTE: In the case of a diesel engine the fuel combusts from a combination of air pressure and heat while a gas engine requires a spark (as in “spark plug”) to start the combustion process.

EXHAUST

In the final stage, after combustion is over the exhaust needs to be expelled so the combustion process can start all over again.

Gas vs Diesel Design

The gasoline engine has a component called the throttle body that varies the amount of air entering the engine, by using a flat valve (butterfly valve). The throttle body supplies the correct amount of fuel needed at the injectors. The action of the throttle body creates a pumping loss, which when combined with the natural drag of the engine, produces a type of natural engine braking. In every day language, the throttle body shuts off the fuel momentarily. Not quite that simple but it’s a simple way to understand it.

Diesel engines do NOT have a throttle body to interrupt or control the flow of air. Air flows freely through a diesel which means that shutting off the fuel (by controlling air flow) would never produce engine braking.

Big trucks with heavy loads, going down a grade — even a little grade — need a way to slow the engine down.

Why?

Because physical brakes, the ones found at each of the wheels — that engage when you put your foot on the brake pedal — will begin to fade long before the load will slow down enough, to be safe on a downhill grade.

If you don’t know what “brake fade” is — here’s a quick and dirty explanation.

Brake fade happens when the brakes are held for too long, or the brakes are hit too often — even pumping or stabbing. Heat builds up. It is possible to set the wheels on fire. Heat causes the brake drums to expand until the brake pads can no longer reach them. In short, you got NO brakes when brake fade happens.

Trucks cannot rely on drum or disc brakes alone to slow down a heavy load on a grade. Jakes are vital for heavy trucks to reduce speed so…

What does slow a diesel engine down?

In short… you have to turn the engine into a giant air-compressor that works against itself.

Here are the basics for how jake brakes work

Skip this if the mechanics don’t interest you BUT… bear in mind that I am no mechanic and the whole point of this article is to make this simple enough that even non-mechanically minded folks can easily visualize and understand it.

Stick with me for just a moment longer. You’ll be happy you did!

A jake brake alters the way the diesel engine normally works. It does this by harnessing the fuctions taking place between the second stage of COMPRESSION and the third stage of COMBUSTION.

What’s happening exactly?

Remember that air comes into the piston during the INTAKE stage. (stage 1)

Next is the COMPRESSION stage. (stage 2)

It’s right there 👉 at the compression stage.

The jake brake harnesses the pressure or resistance in that 2nd stage and instead of letting it COMBUST — as it normally would — the jake opens the EXHAUST port at top-dead-center of the cycle, preventing the piston from going back down, which would produce energy (speed).

To sum it all up — in effect — by letting that pressure out before combustion takes place the jake brake causes the engine to slow down.

So, you’re not stopping the fuel, which wouldn’t work anyway, as I said earlier, but are instead harnessing the pressure build-up in the piston (the compression) and using that to slow the truck down. This turns the engine into one giant air compressor that works against itself slowing it down.

Make sense?

Now that you know how it works, let’s talk about how to use it.

The easiest (and quickest) way to learn how to use your jakes!

I call them “jakes” which is technically incorrect. It’s a “jake brake” not a “jakes brake”. And I don’t care. I like ‘jakes’. Bear with me. I can be stubborn like that.

So…

I see a lot of videos that talk about using the jake brake without doing a whole lot more than showing you the button on the dash or on the steering stalk, that turns the jake on and then they show the possible settings. Usually there are three settings: high, medium and low but there can be more and in fact, several different combinations depending on the make and model.

Here’s the problem

If you know nothing about using a jake brake or your experience is limited — a video that shows you where the buttons are is nice BUT — it doesn’t tell you HOW to use it.

Here are the rules I play by

After starting the truck, the first thing I check are the jakes. I always have the jakes turned on for the driving day.

If I’m heading for the highway the jakes are set to 1 or 2 typically; the lowest or second to lowest setting.

Once on the highway, I set the cruise and then set the ‘speed limiter’ for how much over the cruise control speed the truck will go before the jakes kick in. I usually set this to 2 miles in bigger mountains and up to 3-4 miles over, in smaller hills. I am currently driving a Volvo VNR with a speed limiter. Other makes and models will be different and may not have a “speed limiter” — so don’t worry about that part if it’s not familiar to you.

I have driven Freightliner, Kenworth, Peterbilt, International and Western Star. Every one is a little bit different even among models.

The key here is to KNOW YOUR TRUCK

Every truck is a little bit different when it comes to how the jakes work.

You have to test your jake brakes in non-critical situations to learn how the truck will respond. DO NOT WAIT until you need a jake brake to know how it’s going to respond. It will likely surprise you if you do that.

Speed and Gear

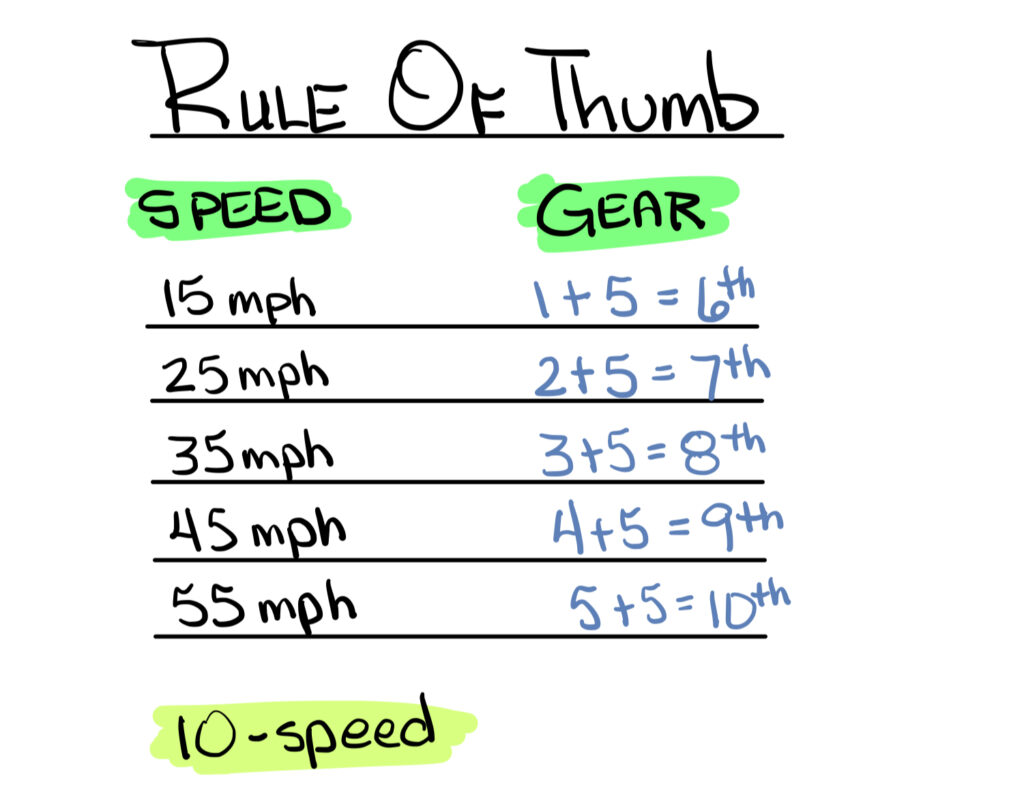

Here’s another one of my drawings. This is a quick-n-dirty speed to gear chart to get us rolling!

What this chart is telling us is a basic “rule of thumb” for what speed the truck will go in each gear up to the “sweet spot” in the RPM’s before it shifts.

Having this rule-of-thumb chart memorized is powerful because it gives you a foundation to work from. Bear in mind that the speeds/gear combinations in this chart are based on level ground.

NOW… let’s apply this to a downhill grade.

The variables you’re dealing with in a truck, going downhill are these:

- the weight of the truck with the load — let’s say it’s 40,000 pounds

- the suggested downhill speed for trucks — let’s say it’s 55 mph (this is a straight road!)

- the percentage of the grade which is usually posted — let’s say it’s a 6% grade for 10 miles

- the level of jakes you will need to go down safely

NOTE: Sometimes you won’t get the distance and sometimes you will. Usually, if it’s a long downhill grade they do post how long in some states. If you’re going down a hill at a 6% grade for 10 miles that’s a lot different than going downhill for a mile or two.

OK… so with these variables in mind,

👉 I know that 55 mph requires 10th gear on level ground from the RoT chart

👉 I know I’m going downhill at 6% and I know that’s a pretty good grade

👉 I know the truck WITH the load weight is roughly 40,000 pounds. And yes! – you need to know the weight of your truck empty so you can add the loaded weight for the total

👉 I know how much compression I’ll get with the jakes set at 3 which is the highest level. Not MAX. Max is there if you need it.

SO…

What gear would you pick to start down that hill?

If you guessed 9th, which is one gear below the rule-of-thumb on level ground with the jakes set to 3 (highest level before MAX), you did great! If it were me, I’d set the gear to 8th and see how it runs if I’ve never gone down that mountain before.

Remember — you can always go faster. Slowing down is the harder part.

AUTOMATICS

If you drive an automatic you can set the cruise-control to 50 and the speed limiter (if you have one) to 52. From there click down on the cruise button to lower your speed if necessary. When the RPM’s reach around 1500 on a downhill run the jakes usually kick in. Just remember if using the cruise control that if you’re not holding the speed you want, click the cruise button to lower the cruising speed and the jakes will kick in sooner.

I went down a 6% grade today that was 10 miles long. Temperature was 58 and dry. Box was empty on our way o a pickup, so just the weight of the truck. Set the cruise at 52 and the limiter to 54. The truck sat at 54-55 all the way down a long straight hill. It’s a wonderful thing.

IF THE ROAD IS CRUVY — I’d go 5-10 mph slower than the posted speed. I’d set my cruise control to 48, my speed limiter to 50 and push the cruise button even lower if the truck isn’t holding the way I want it to.

There are times, depending on the weight in the box, you might need to drop down 2 gears from the RoT. Usually it’s not more than that… usually.

OK — How To Learn Your Jakes The Easy & Best Way — Quickly!

When I’m 2 miles away from my exit I begin planning ahead. At .5 miles from the exit, I put on my turn signal (yes, that far in advance so people behind me can make a lane change if they want to). The cruise goes OFF and the jakes are set to 1 or 2, while feathering the fuel to maintain a highway speed between 50-60.

As I approach the exit, I start pulling the jakes down. If 2 is not enough — depending on how long the off-ramp is — I might need to pull it down to 3 or even B(max) to slow the truck down as I get to the offramp.

After the jakes engage — if for example I used ‘max’ to slow the truck down — I let the truck breathe and before it down shifts I pull the jakes back up so the next jake application isn’t as strong. You can switch between the settings of your jakes as the truck slows down.

If you keep the jakes at the strongest setting, as the truck downshifts and loses speed, the braking power is going to feel even stronger. Tap it down and let the truck continue to downshift. As it slows down more and more the jakes will eventually not add much which is when I use the brake pedal.

If it’s a rest area with trucks parked in the entrance, I will slow more before actually exiting the highway. If there’s ice or snow I’ll be slowing while on the highway, watching my mirrors for people behind me who aren’t paying attention.

SIDENOTE: Never let a car or truck behind you push you into a bad situation. Always hold your space.

As I exit the highway, I use only my jake brake to slow the truck down. I usualy don’t even touch the brake pedal until at or below 20mph.

Yes, it is possible to come down a mountain without touching your brake pedal

I have driven through the biggest mountains in the U.S., without touching my brake pedal one time. If you can learn to run the mountains using only your jake brakes, you’ll never have to worry about brake fade, catching your truck or trailer on fire or not having enough braking power when you need it most.

Please, if you take nothing else away from this article understand that it’s very possibble to catch a truck on fire from over-using the brake pedal. When you see a truck smoking as it goes down a mountain you can rest assured that driver made a mistake. It’s that simple and it can happen to anyone.

The way to learn how to use your jakes properly STARTS with practicing.

Use your jakes for ALL the braking you possibly can. Learn how the truck reacts. Learn how much is too much. Learn how much is too little. Learn how to switch seamlessly between the levels of jake that is applied. Learn how the truck reacts to each level of jake break.

If you exit the highway using your jake brakes, you’ll learn quickly. Try not to use the brake pedal first. Use your jakes first.

If you have a truck with straight pipes, you’re certainly not who this article was written for. If you’re driving a manual truck with straight pipes and reading an article about jake brakes, meant for inexperienced drivers you have to send me a note and tell me how that happened! Please, post your comments below. 🙃

If you’re a new driver — or — you haven’t understood jakes until now, I’d love to hear from you. Try these ideas and let me know how it works for you, what you learn and whether or not this has helped you.

I appreciate that you made it all the way to this last paragraph and as a reward I’m going to tell you a cute little joke.

Your Reward!

A trucker is hauling penguins when a police officer pulls him over and says, “What are you doing? You need to take those penguins to the zoo. Here are some directions.” The next day, the officer sees the same trucker in the same truck hauling more penguins. The officer pulls him over and says, “Didn’t I tell you to take those penguins to the zoo?” The trucker replies, “I did, and it was a lot of fun! Today I’m taking them to the movies.”

Enjoy the big road!

Andrea

Loved the article, it is hard to find information on using the jake brake, which is so valuable. Appreciate the info.

I agree! I was surprised. Someone asked a question about jakes and we didn’t have the time to talk. I went looking later for a video I could send and realized there was so little, so I decided to write this article. Thank you for posting this — you made my day! 🙂